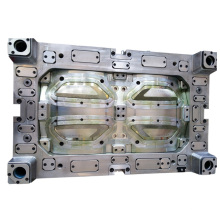

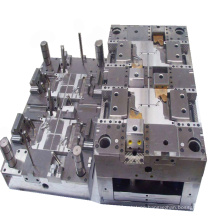

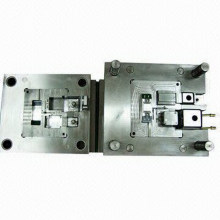

Professional Electronic Precision Mold Parts Core Parts

Professional Electronic Precision Mold Parts Core Parts

| Payment Type: | L/C, T/T, D/P, Paypal, Money Gram, Western Union |

|---|---|

| Min. Order: | 1 |

| Productivity: | 50sets / Month |

|---|---|

| Place of Origin: | Dongguan China |

| Supply Ability: | 50sets / Month |

| Certificate: | CE, ISO, SGS, FDA |

Basic Info

Model No.: LW-02351

Product Description

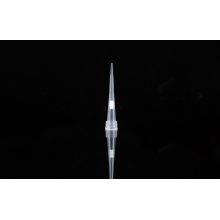

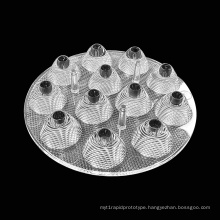

Model NO.: LW-02351 Surface Finish Process: Heat Treatment Plastic Material: ABS, PMMA, PC,San, PA66+Gf, Tritian ,PE, Pet, POM Application: Car, Household Appliances, Commodity, Electronic, Home Use Design Software: Ug, PRO/E, Master Cam. Solidworks, Autocad Certification: CE, ISO, SGS, FDA Customized: Customized Trademark: lead well Origin: Dongguan China Shaping Mode: Injection mould Mould Cavity: Single or Multi Cavity Process Combination Type: Single-Process Mode Runner: Cold or Hot Runner Installation: Fixed Standard: Hasco, Dme,Misumi Mold Life: 3000,000-1,000,000 Shots: Mold Steel: P20, H13, 718h, Nak80, S136, 2311 234 Specification: CE. ROHS, SGS HS Code: 84807190 Plastic Electronic Precision Mould Parts Core Parts

Specifications:

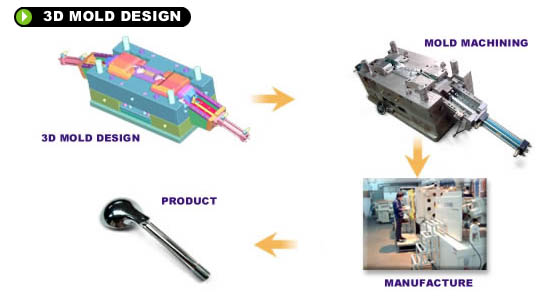

1. Plastic Mould making & Injection moulding

2. Design assistance, STP/igs, X_t format

3. High quality control and economic price

4. High-volume production

5. Continuance after-sale service support

Lead Well Technology Co., Ltd is a professional manufacturer in Plastic Injection Mould, plastic parts injection, and Rapid Prototype manufacturing,

The advantage of our company is as follow,

Mould Tooling: Almost 80% moulds were exported to Europe, Japan and USA in various fields for these years, We have rich experience in known what's the clients request. But also, we deeply understand what a important the small details of tooling, such as cooling system, thread holes, ejector pin types, O-ring grooves and so on, and also how to ensure the moulds run smoothly in mass production.

Plastic part injection: We have 15 sets injection machines in the factory, to ensure the fast delivery both in small and big order.

Please visit our website to get more information about our company

Looking forward to having a good beginning for our reliable cooperation!

Contact us if you need more details on Plastic Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Mould、Computer Plastic Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Specifications:

1. Plastic Mould making & Injection moulding

2. Design assistance, STP/igs, X_t format

3. High quality control and economic price

4. High-volume production

5. Continuance after-sale service support

Lead Well Technology Co., Ltd is a professional manufacturer in Plastic Injection Mould, plastic parts injection, and Rapid Prototype manufacturing,

The advantage of our company is as follow,

Mould Tooling: Almost 80% moulds were exported to Europe, Japan and USA in various fields for these years, We have rich experience in known what's the clients request. But also, we deeply understand what a important the small details of tooling, such as cooling system, thread holes, ejector pin types, O-ring grooves and so on, and also how to ensure the moulds run smoothly in mass production.

Plastic part injection: We have 15 sets injection machines in the factory, to ensure the fast delivery both in small and big order.

Please visit our website to get more information about our company

Looking forward to having a good beginning for our reliable cooperation!

| Item Name | OEM Plastic Injection Mould for plastic parts |

| The company's strength | 1). Efficient team in exporting mould 2). Delivery on time 3). Excellent equipment 4). High quality and competitive price |

| Core & cavity material | Saarstahl, Assab, AISI & JIS, DAIDOSTEEL, ALCOA, S136, 1.2311, 1.2738, NAK80 2344, 420, 2083 etc |

| Plastic material | ABS, ABS+PC, PP, PS, POM PVC,TPE, TPU ,Acetal, PA66 PA6, PA66+30%GF, PPS, etc |

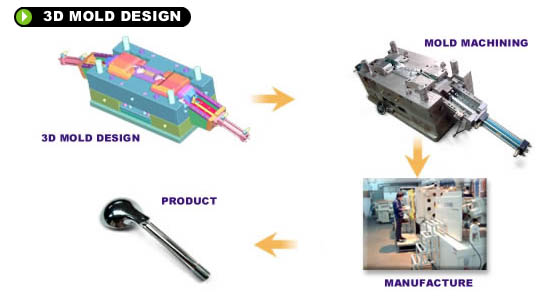

| Main processing Equipment | CNC, wire cutting, Grinding machine, Lathe, Drill Press, EDM center |

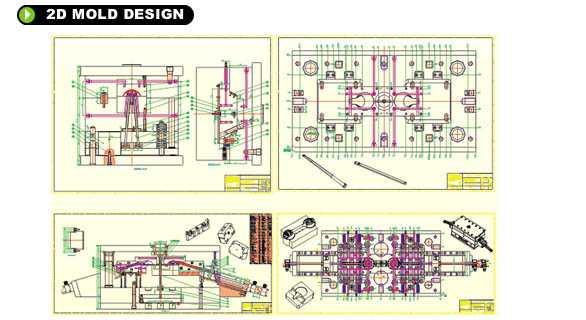

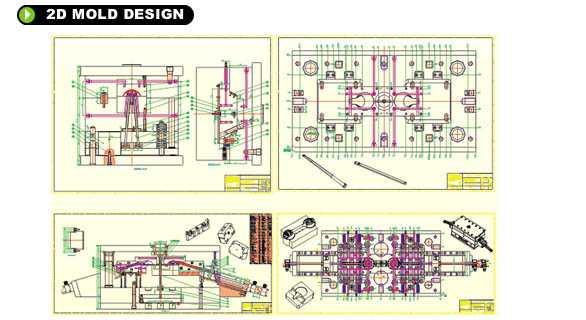

| Practicable software | Pro/E, UG. Solidworks, AUTO cad |

| Business Scope | 1). Plastic Mould Design 2). Mould making/Mold making/Tooling manfuacture 3). Plastic parts injection 4). Reverse Engineering 5). Rapid Prototype manufacturing 6). Sheet Metal Prototype manufacturing |

| Primary Competitive Advantages | 1). Quickly response and complete understanding 2). The most competitive and reasonalbe price 3). Short delivery time and prompt delivery 4). Well and High Quality Control 5). Customer's Designs and Logos are welcome. |

Contact us if you need more details on Plastic Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Injection Mould、Computer Plastic Mould. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Precision Plastic Injection Mould

Premium Related Products

Other Products

Hot Products

Pool Fence Glass SpigotElectronics Plastic Part with Spray CoatingBrass CNC Lathe Thread PartSilicone Rubber Mould for FranceGarden Machine Plastic Injection Moulding ProductsWasher Plastic Part Injection Moulding PartsPipe Fitting Plastic Injection MoldMotor Vehicles Aluminum Die Casting MoldPlastic Mould for Automotive PartsHousehold Products Plastic Injection MoldElectronics Plastic Cover Injection MouldClear/ Transparent Vacuum Casting Prototype for Home Appliance (LW-05001)High Quality Punching Bending Sheet Metal Prototype (LW-03001)Hi-Quality Injection Parts in Remote Control, China Manufacturer, Double Material Injection (LW-10013)Precision CNC Machining Prototype / CNC Model (LW-02003)SLA / SLS, Rapid Prototyping 3D Printer Prototype/Mould /Molding