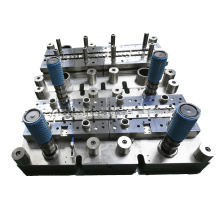

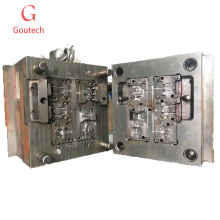

Automotive Door panel plastic injection mould

Automotive Door panel plastic injection mould

| Unit Price: | 10000 USD |

|---|---|

| Min. Order: | 1000 Piece/Pieces |

| Packaging: | Wooden box |

|---|---|

| Productivity: | 300 sets/year |

| Brand: | Ceeto |

| Transportation: | Ocean,Air,Land,Express |

| Place of Origin: | China |

| Supply Ability: | 20pcs/month |

| Certificate: | ISO |

| HS Code: | 8480790090 |

| Port: | Ningbo,Shanghai |

Basic Info

Model No.: CT-10121

Click on the follow link to find out more information: https://www.ceetomold.com/automotive-exterior-plastic-injection-mould/

Company Info

- Company Name: Zhejiang Ceeto Mold Co.,Ltd.

- Representative: WANG JUAN

- Product/Service: Plastic Injection Molds for Automotive , Plastic Injection Molds for Washing machines , Plastic Molds for air condition , Medical Consumer Goods Plastic Injection Mould , Die Casting Moulds and Products , Plastic Molds for Daily commodities

- Capital (Million US $): 10,000,000RMB

- Year Established: 2018

- Total Annual Sales Volume (Million US $): US$1 Million - US$2.5 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 2

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: No.78 Baiyunshan Road, Ningbo,China

- Contact Person: Ms. Jenny Wang

- Tel: 86-574-86863623

Premium Related Products

Other Products

Hot Products

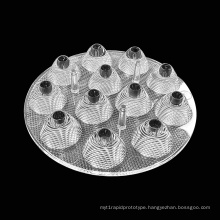

Pool Fence Glass SpigotElectronics Plastic Part with Spray CoatingBrass CNC Lathe Thread PartSilicone Rubber Mould for FranceGarden Machine Plastic Injection Moulding ProductsWasher Plastic Part Injection Moulding PartsPipe Fitting Plastic Injection MoldMotor Vehicles Aluminum Die Casting MoldPlastic Mould for Automotive PartsHousehold Products Plastic Injection MoldElectronics Plastic Cover Injection MouldClear/ Transparent Vacuum Casting Prototype for Home Appliance (LW-05001)High Quality Punching Bending Sheet Metal Prototype (LW-03001)Hi-Quality Injection Parts in Remote Control, China Manufacturer, Double Material Injection (LW-10013)Precision CNC Machining Prototype / CNC Model (LW-02003)SLA / SLS, Rapid Prototyping 3D Printer Prototype/Mould /Molding